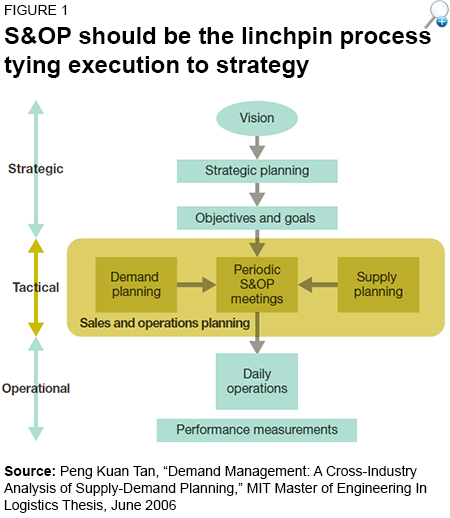

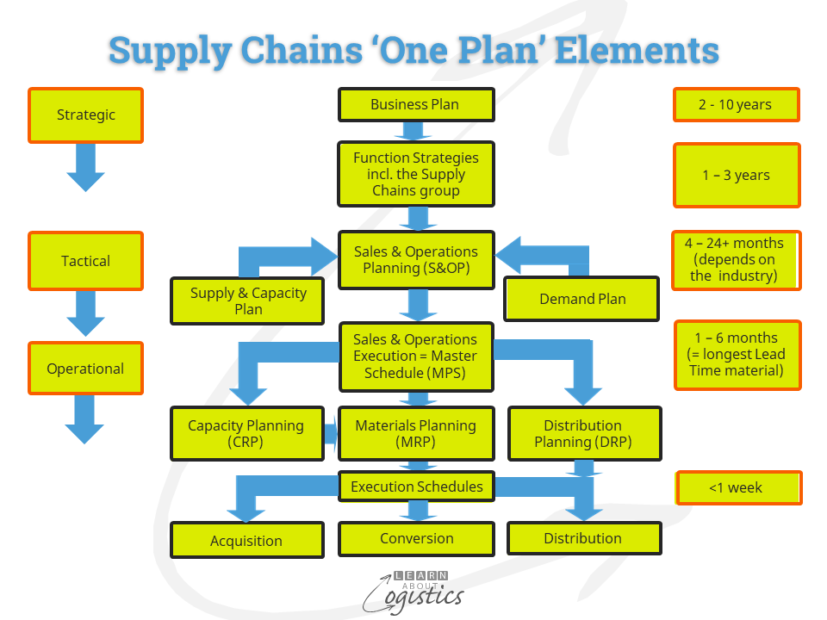

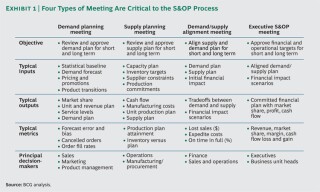

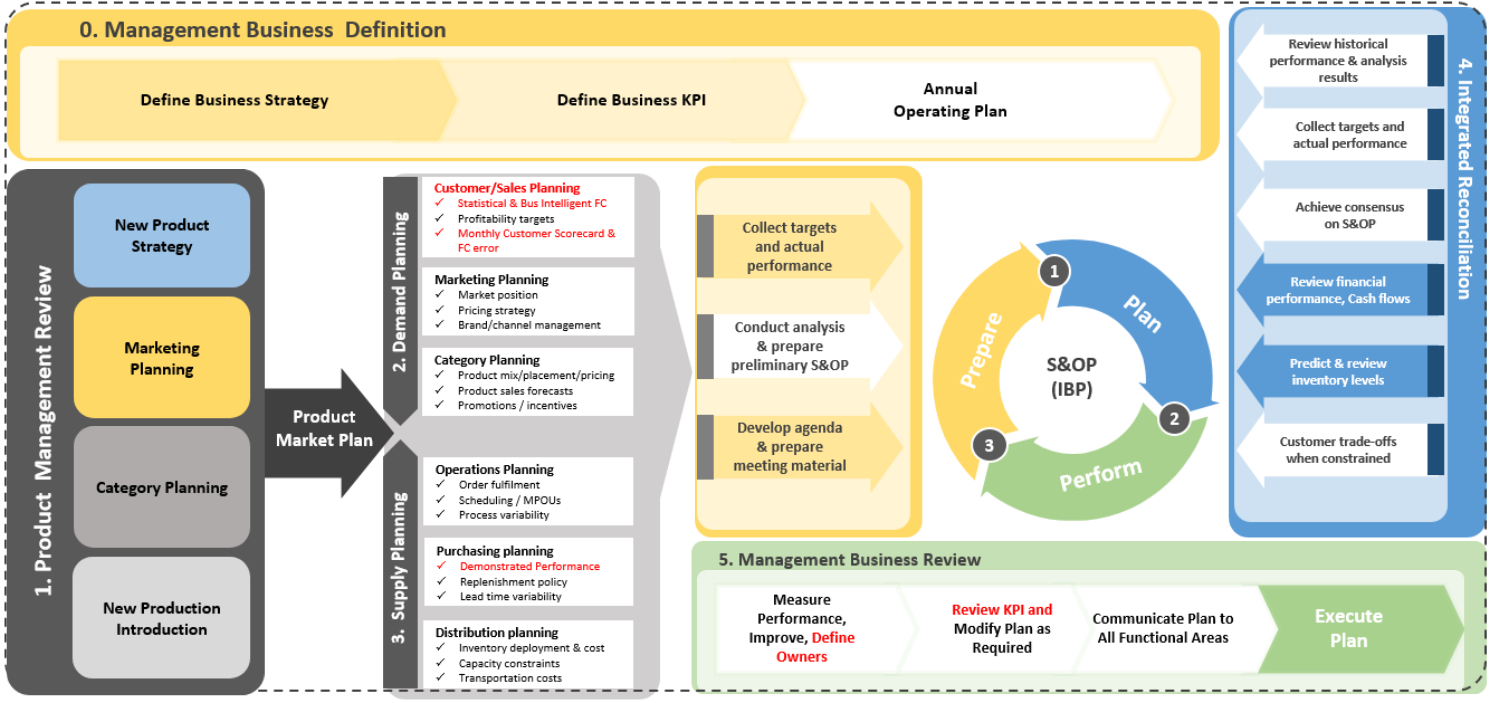

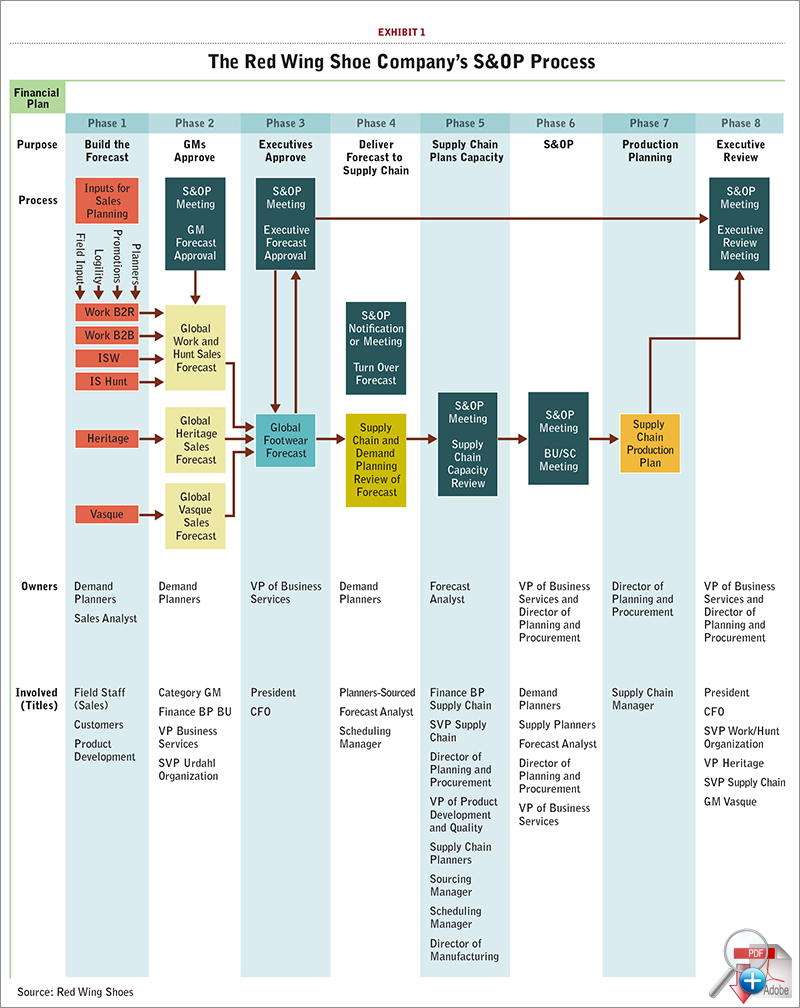

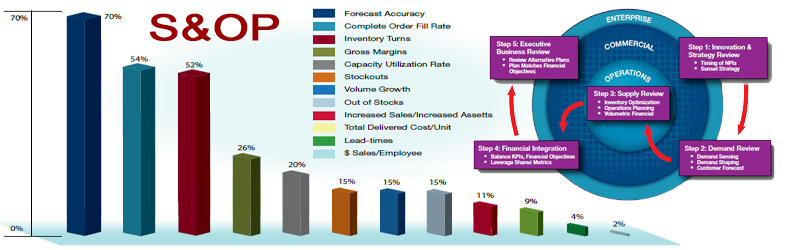

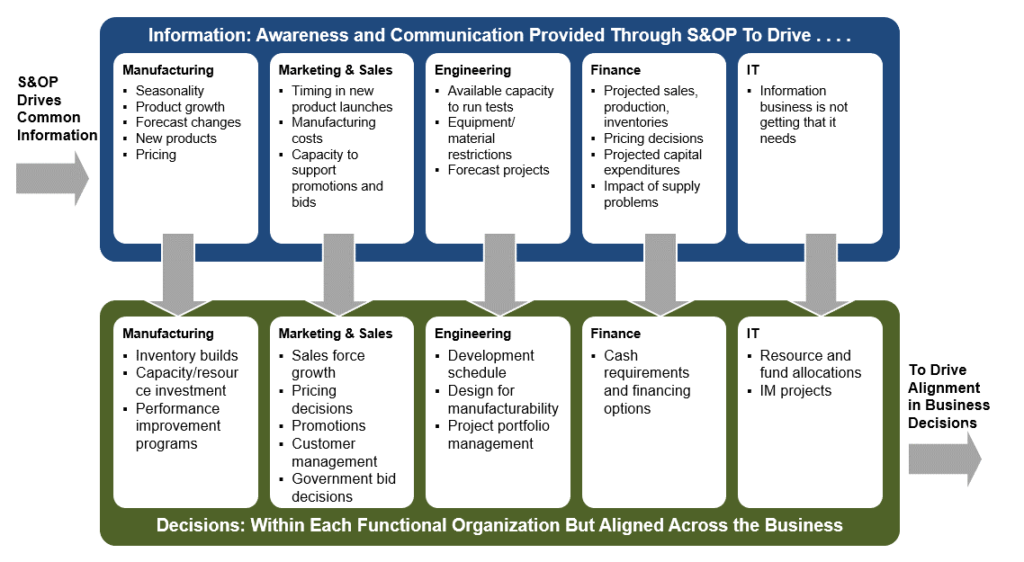

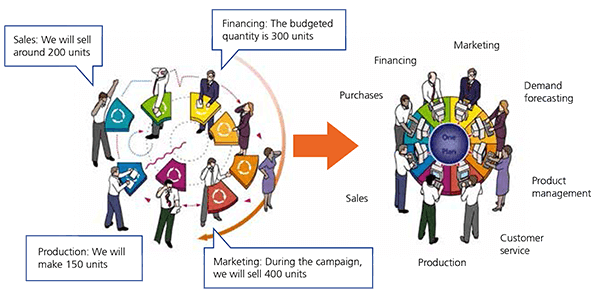

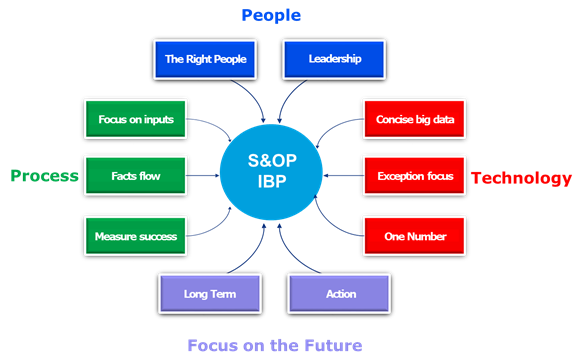

Sales & Operations Planning is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantageSales and Operations Planning (S&OP) is an offshoot of production planning and owes its evolution to practitioners of operations management ItThere must be tight alignment between the operating plans and the financial plans through appropriate unit of measure conversions into currency S&OP is crossfunctional and collaborative It involves, at a minimum, Sales/Marketing, Operations/Supply Chain, Product Development, Finance, and General Management

What Is S Op How S Op Works Demand Planning Com

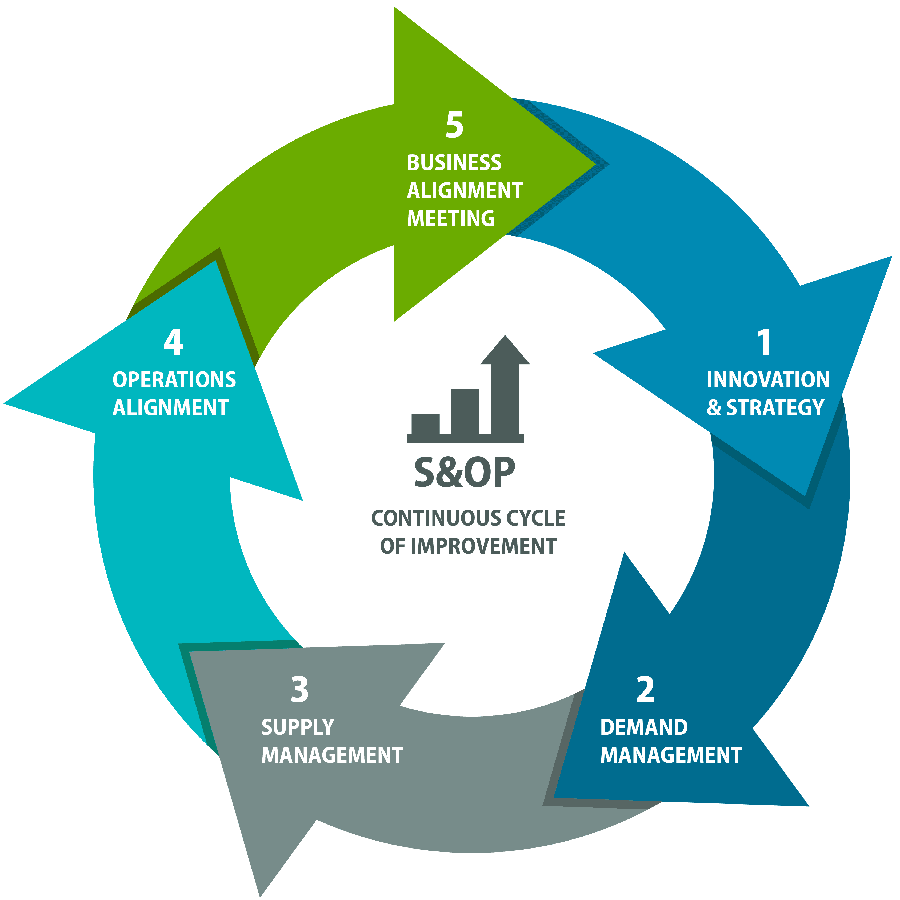

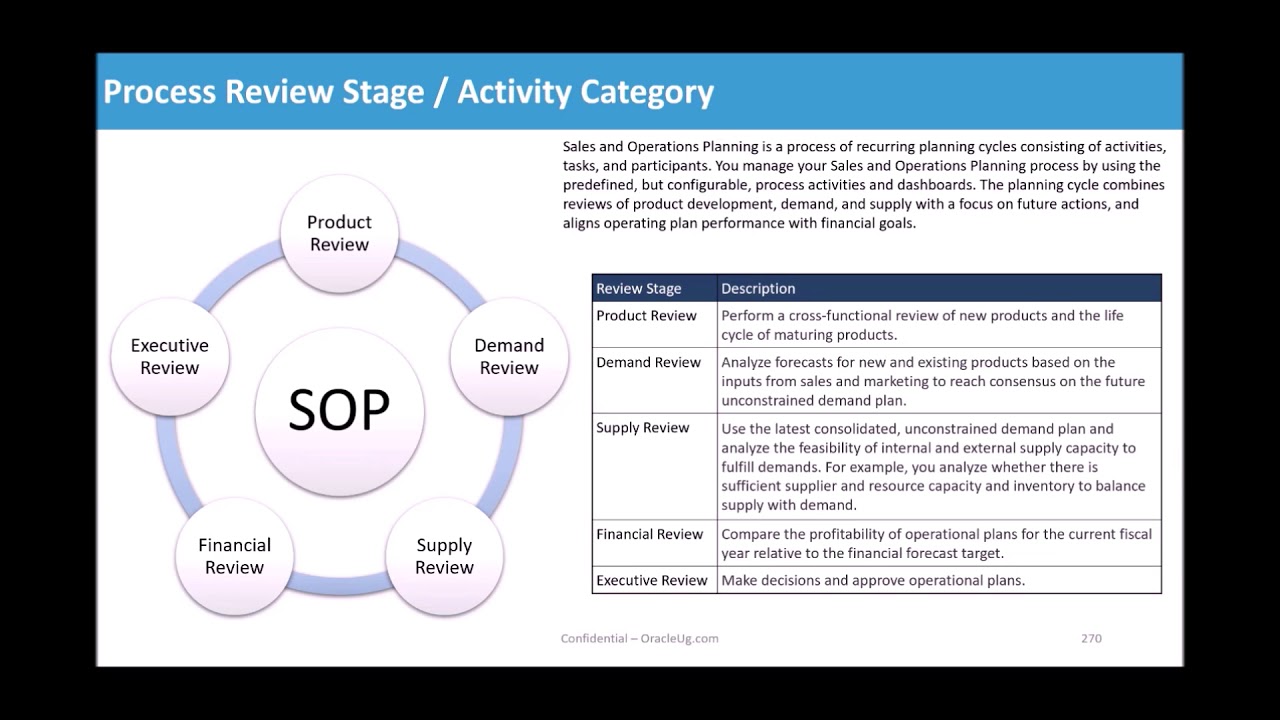

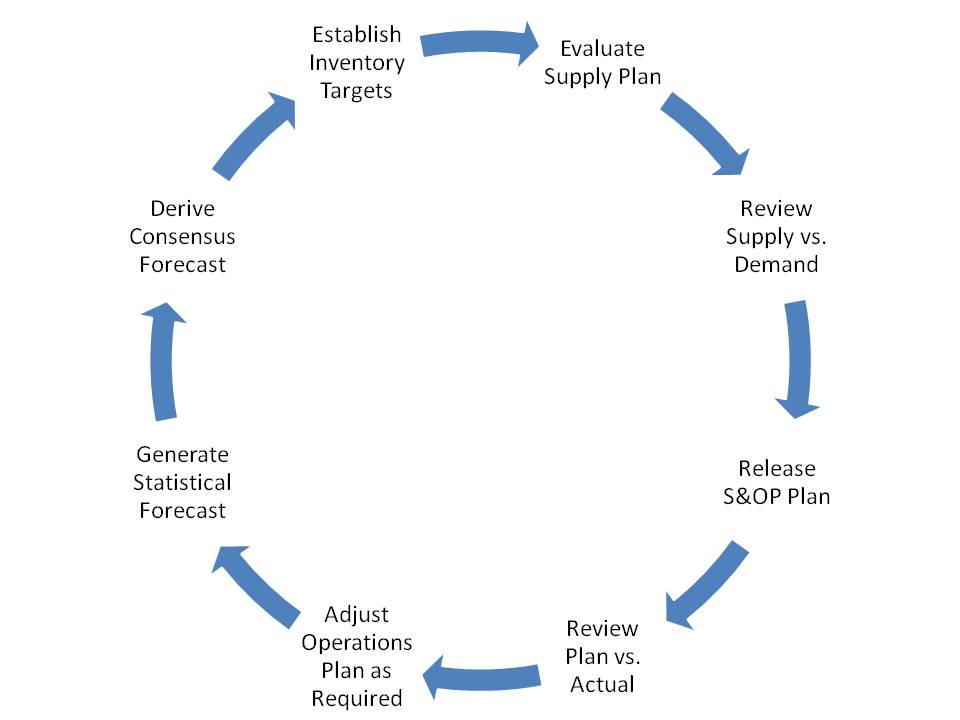

S&op planning cycle

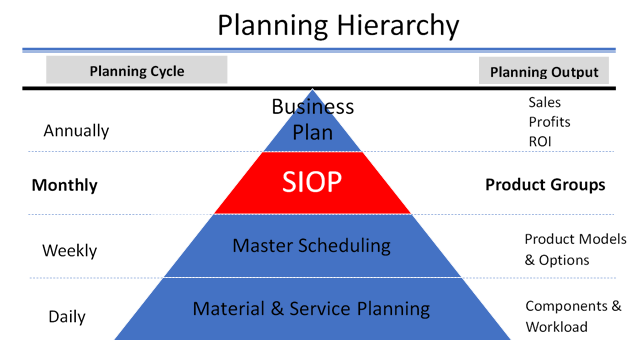

S&op planning cycle-Top level planning technique to provide overall rates of sales and production, and backlog and finished goods inventory positions In a cellular or flowline based operation, SIOP provides the daily run rates for these product families SIOP is the key business process that derives from the strategic plan, and from whichAn effective sales and operations planning (S&OP) process guides business decisions, provides key problem solving strategies, gives executives greater control over the enterprise and drives overall business success Establishing and sustaining highfunctioning S&OP processes within an organization can be extremely difficult, however

S Op Introduction

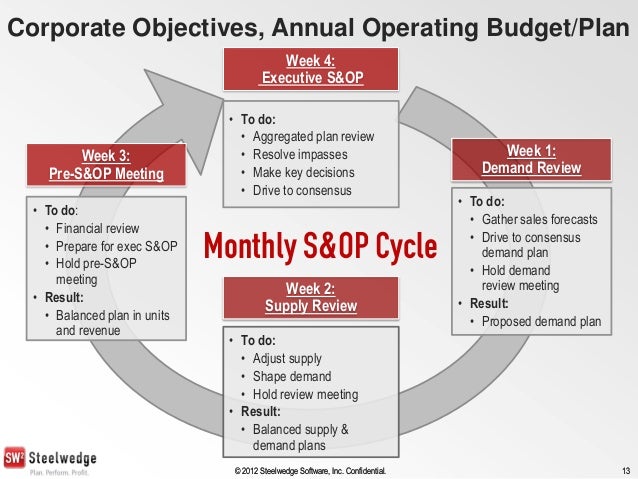

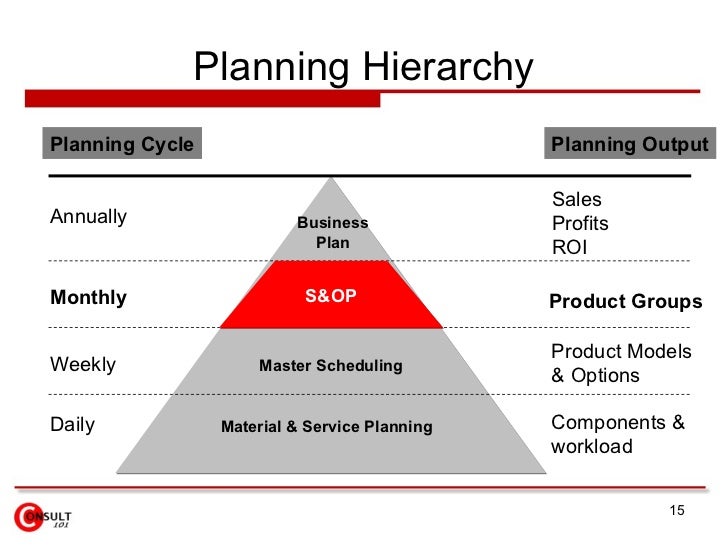

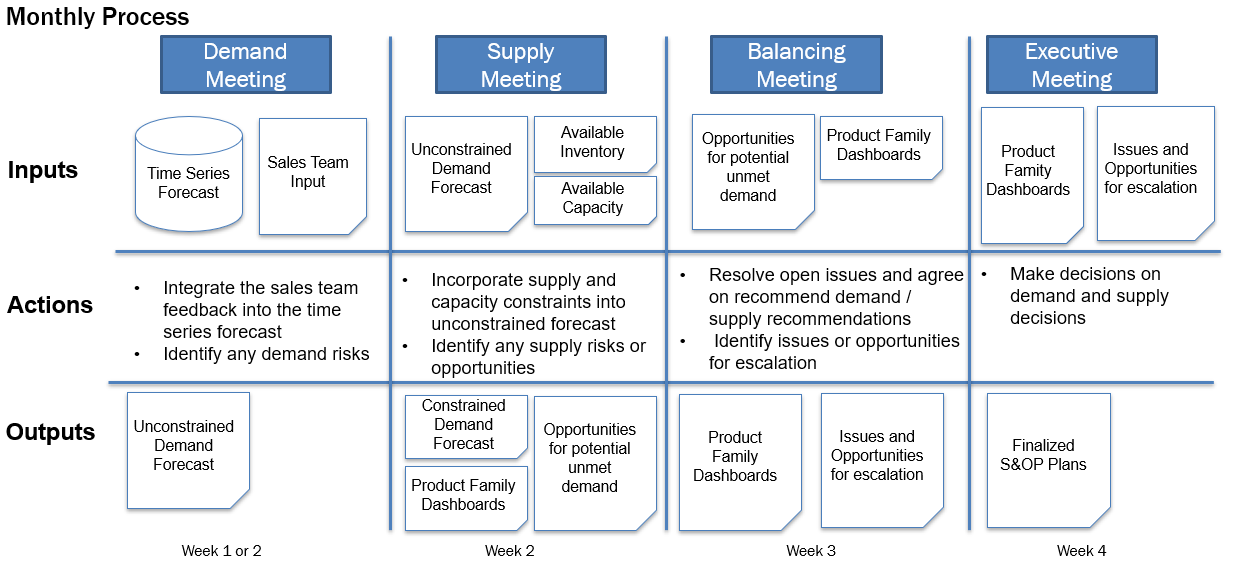

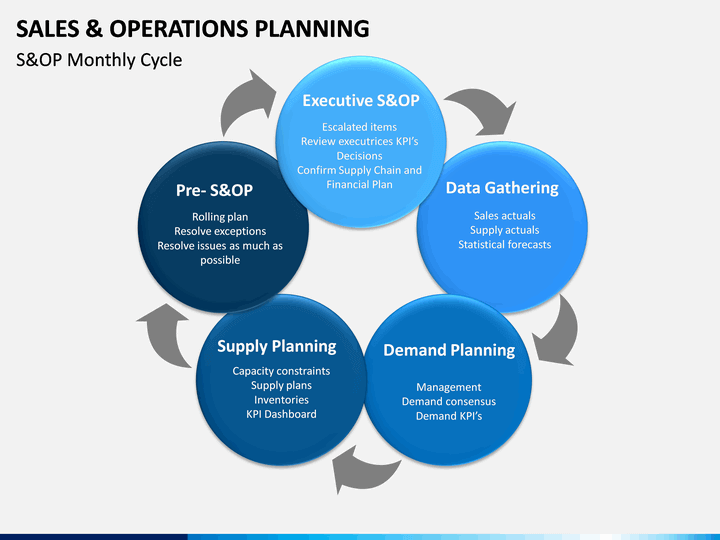

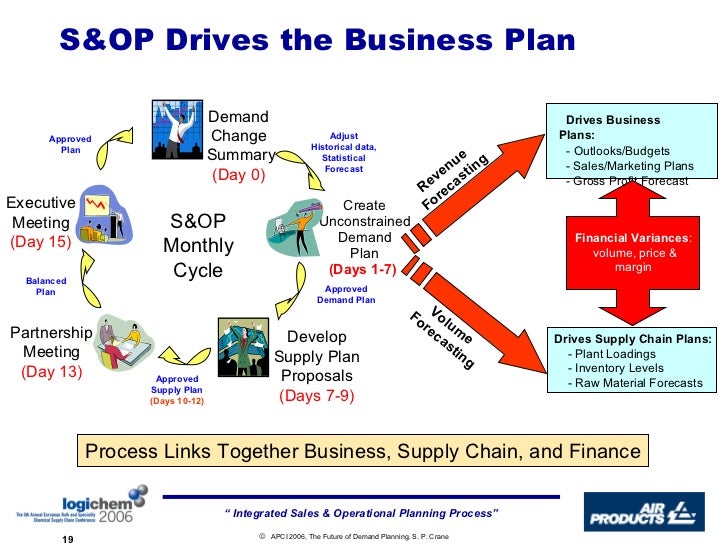

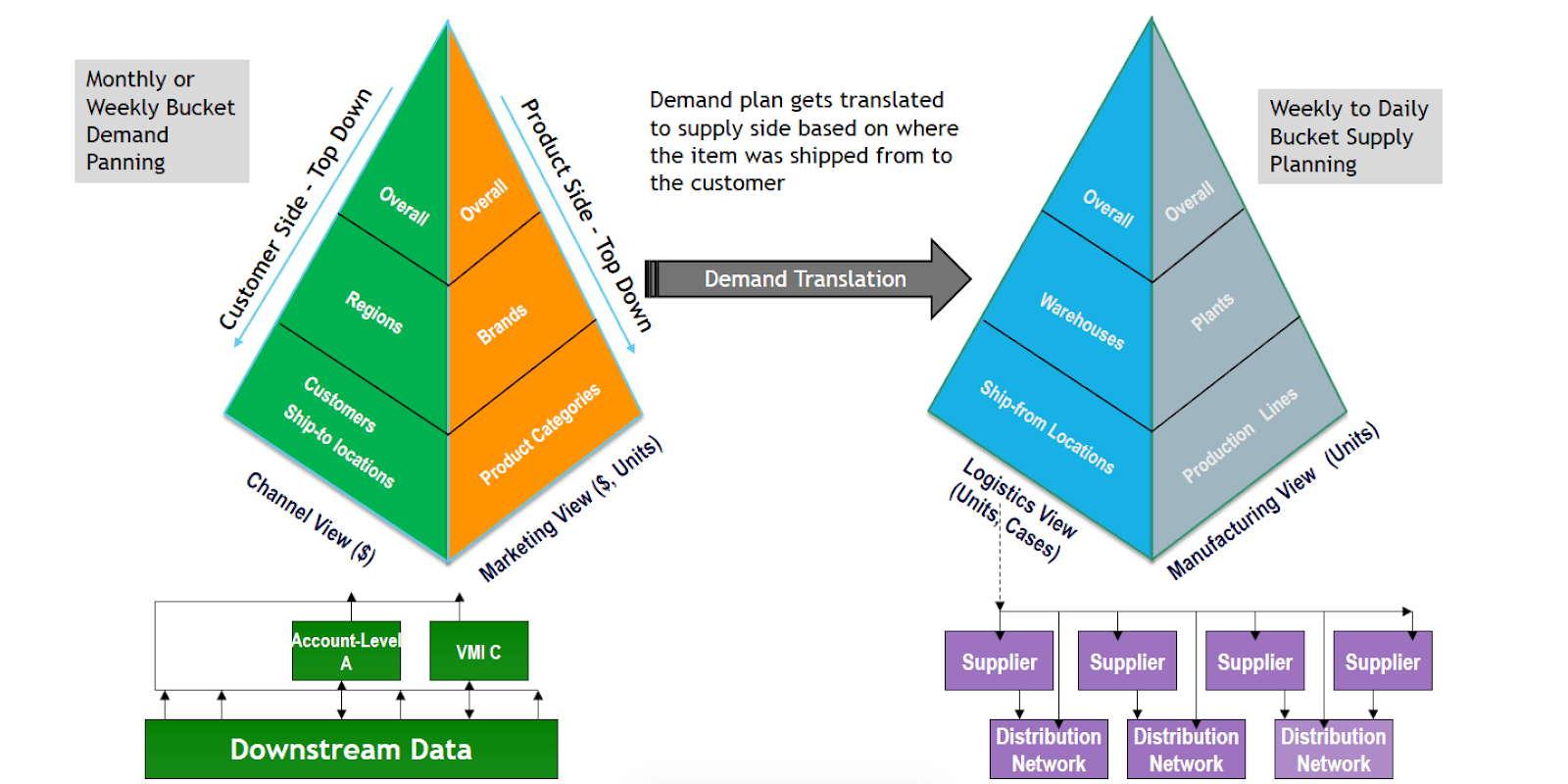

The same is true for supply chain planning Sales and operations planning (S&OP) focuses on a tactical horizon from 324 months and has completely different objectives than sales and operations execution (S&OE), which covers the near term Sales and Operations Planning Get quick, clear insight into the impact changes to your plans have on operations – so you can set financial targets, measure progress, identify gaps and close them quickly The speed in which scenarios can be created and analyzed has gone from 24–48 hours to 10–30 minutes in our S&OP process withS&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is to enable executives to make better

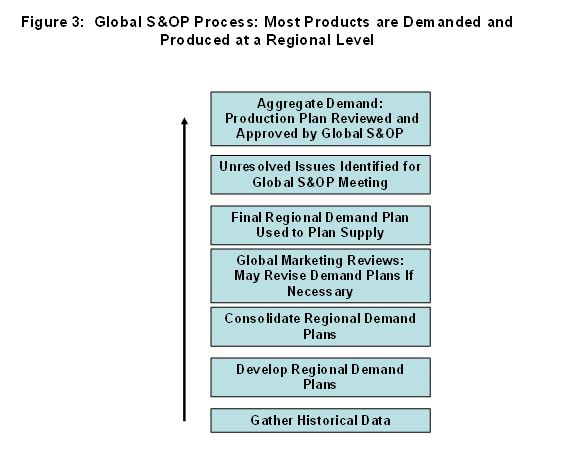

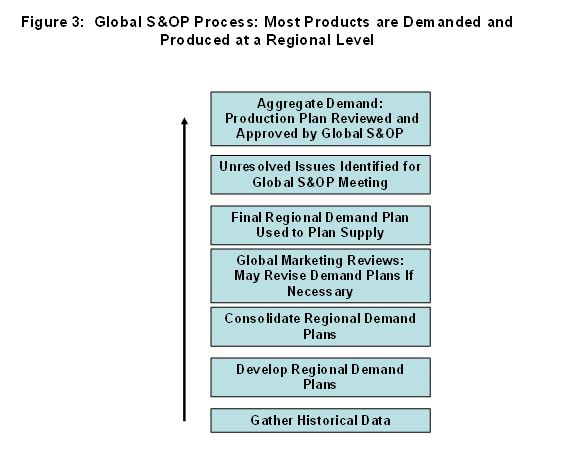

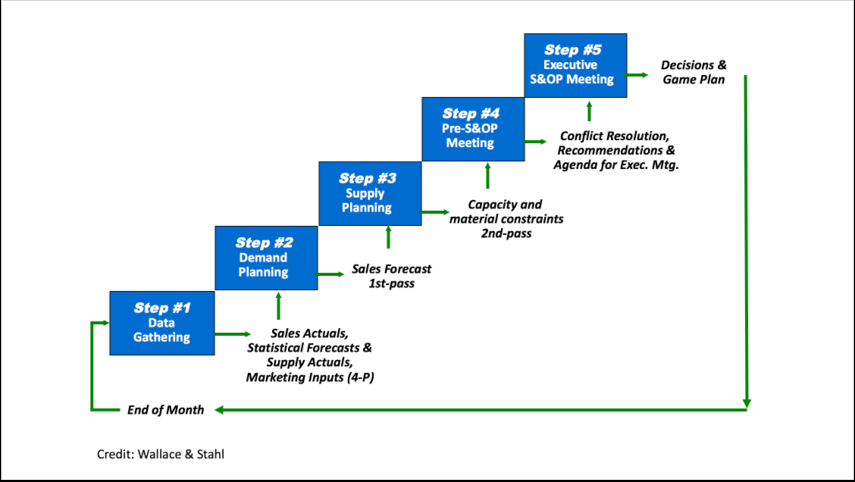

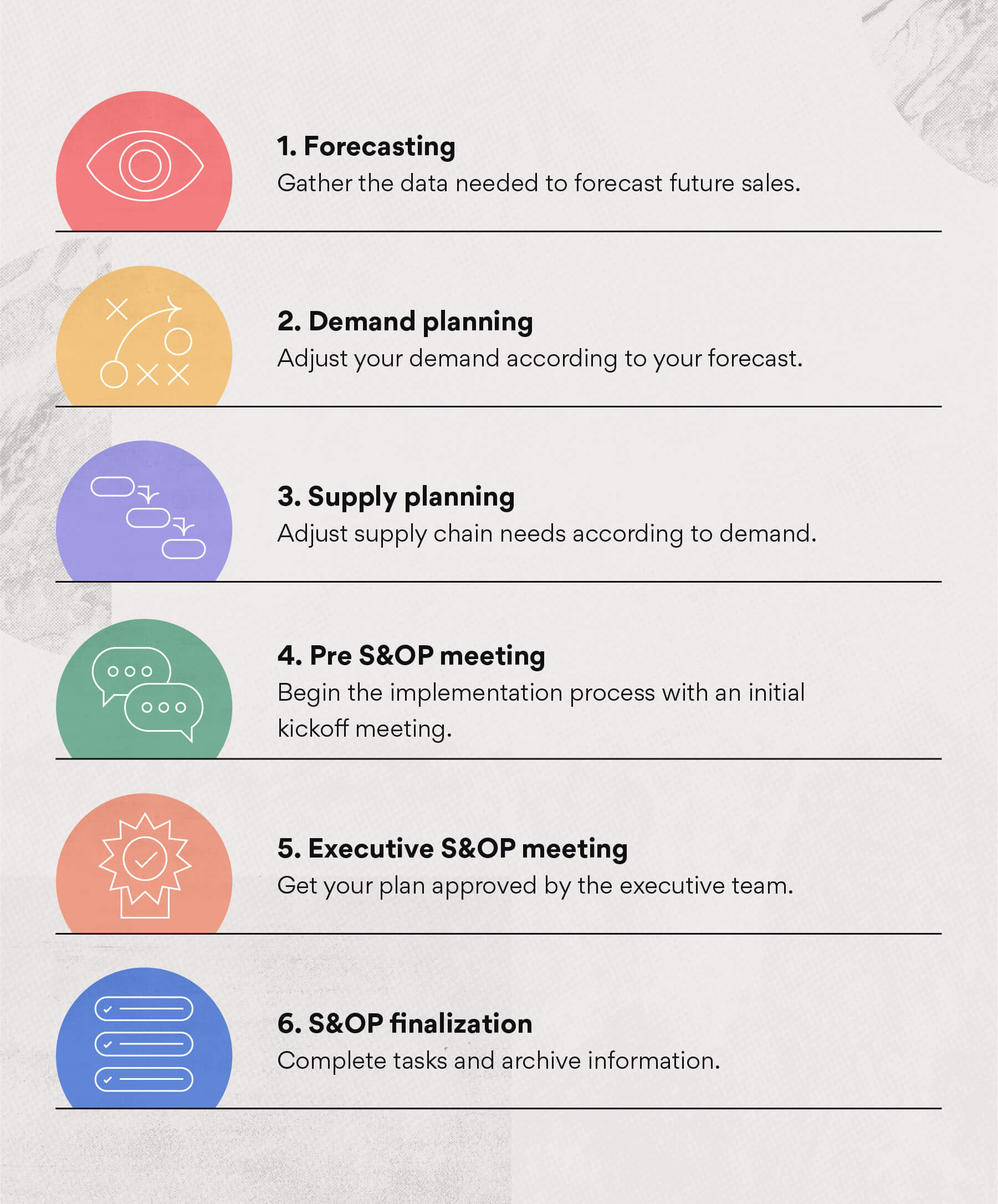

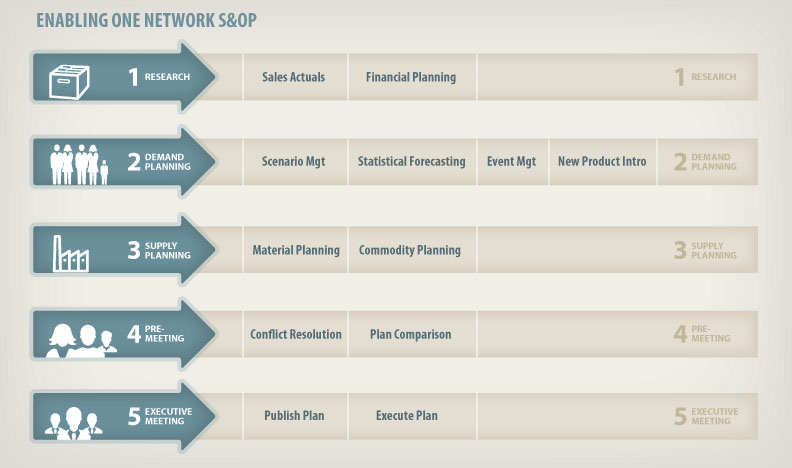

Dick Ling, cofounder of StrataBridge introduced the concept of Sales and Operations Planning in the late 1980s in his book 'Orchestrating Success', and StrataBridge people have focused on S&OP and supporting processes such as forecasting and new product development ever since From high level planning through to detailed designS&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing theTo accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps

Part of a Sales and Operations Planning (S&OP) process 4 Performance measurements Larry Lapide, 06 Page 10 1 Forecasting Organization A integrated approach is driven by a stakeholder organization that is chartered Life Cycle Î Uses prior history to S&OE smooths the daytoday volatility for more controlled operations In Set Up Sales and Operations Execution Process to Support the S&OP Cycle Pukkila explains, "Because of the shortterm view to the supply chain and manufacturing management, the daytoday noise and volatility seem worse than it may be The result in many companies in this situation is that theyProject members of new projects Key Users, IT staff, Project Managers, etc

1

What Is S Op How S Op Works Demand Planning Com

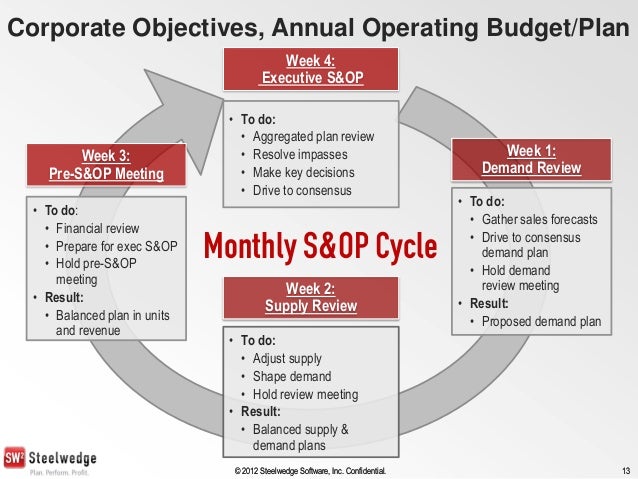

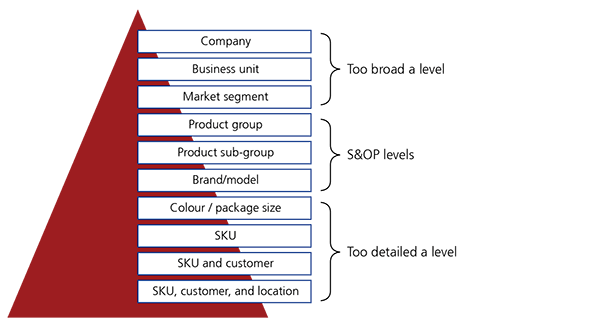

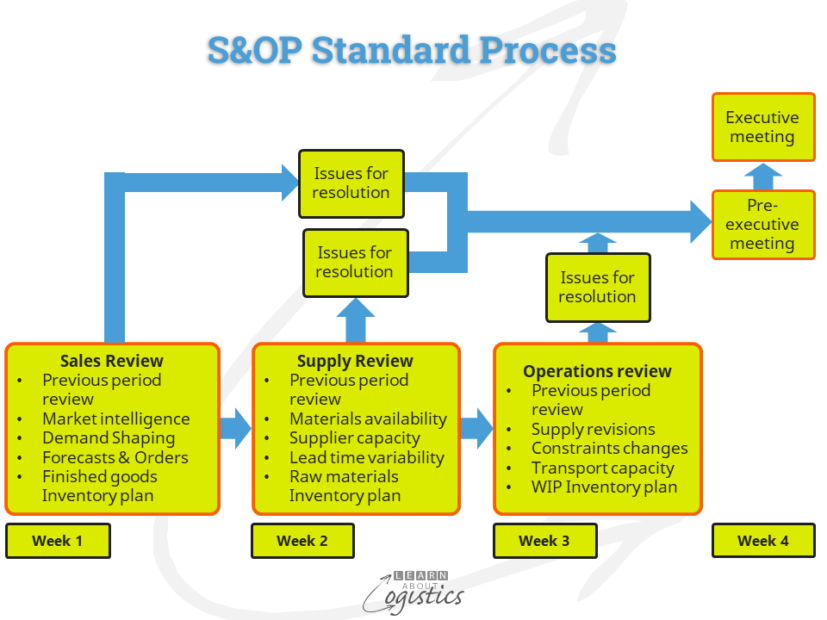

This standstill is threatening the very existence of S&OP The only way to further mature S&OP is to academically define it, govern it and integrate it with other academic disciplines The times since Sales & Operations planning (S&OP) was born in 1987 as a solution for operational issues are long goneSales and operations planning is typically led by senior management and is most often executed monthly It is an iterative process in which results from one planning cycle are compared with the next to provide management with trend information from across the business Although S&OP planning can be extremely strategic, involving seniorlevel executives and pivotal decisions, most companies focus on the transactional level and, to a lesser extent, the operational level the product's lifecycle stage, and supply chain impact Since resources must be allocated across the product portfolio—and some areas

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

What Is S Op How S Op Works Demand Planning Com

S&OP – Planning Fences No Changes to plan accepted – "frozen" Customer Order Daily Production Schedule FG Ship Weekly Schedule Issued Changes to plan accepted – 5% Changes to plan accepted – 10% Changes to plan accepted – % Emergencies only accepted Forecast Monthly S&OP 48Sales and Operations Planning (S&OP) is a powerful approach that seeks to synchronize demand, capacity, and inventory When implemented well, S&OP is an efficient process that ensures cost and inventory optimizations while improving service levels If done successfully, it is the backbone of a company's operations and an essential contributor Sales & Operations Planning Collaboration Contextual Process Orchestration Contextually organize People, Documents, S&OP Process Steps, S&OP Data, Action items, Decisions, Alerts, etc around the S&OP Process Define and orchestrate the S&OP process (s) Enable People to stay on top of relevant, contextual updates

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales Operations Planning Why Is S Op Important

‐ S&OP reporting mechanisms enable the S&OP planning teams to identify when actual performance has deviated from the plan ‐ The S&OP process enables the entire management team to understand the challenges confronting the organization and to act upon them in proper priority or focus S&OP Demand Planning Demand Management Supply Planning Product/ Brand Plan Illustrate the interrelationships of SBUs/divisions within the enterprise Time Horizons The S&OP planning horizon is typically in the range of 12 – 24 months, but this can differ depending on specific circumstances (one of my clients had a planning horizon of 3 – 6 months) Here is a quickstart guide on how to implement S&OP Process A robust S&OP process description which is deployed with discipline and consistency Systems Providing effective and wellintegrated systems to facilitate execution of a regular monthly planning cycle People Building capability across the enterprise functions and creating the

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales And Operations Planning Relex Solutions

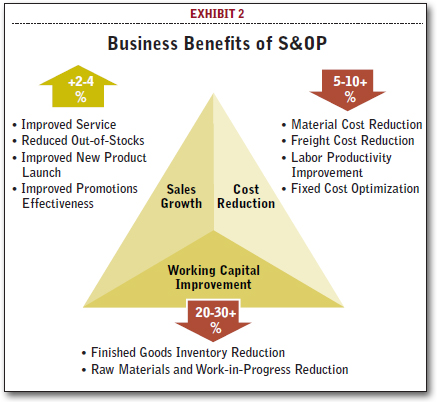

The S&OP process, then, is integral to effective business planning, both in the long term and shorter term S&OE often gets rolled into S&OP because it can be seen as an extension of S&OP The S&OE process, however, focuses on a much more immediate time frame, usually zero to three months Again, this period may vary in different industriesSales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plansS&OP carries enormous benefits in terms of lower inventory costs, higher productivity, and greater customer satisfaction Top supply chain planning solutions, such as DemandCaster, increase advantages further still by enabling you to use the S&OP plan to drive requirements planning and also to move straight from planning to execution

S Op Process

Sales And Operations Planning Cycle Chainsequence Inc

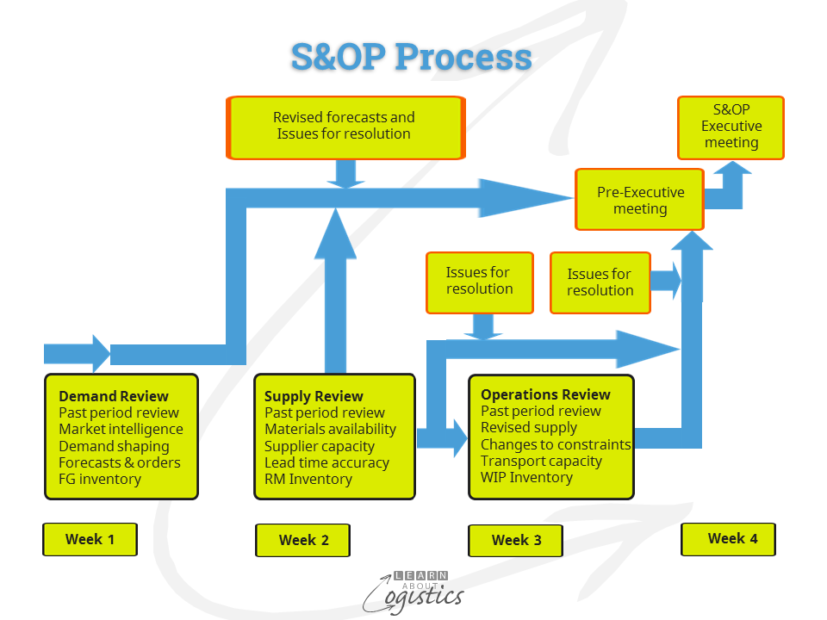

Sales & operations planning cycle An interactive classroom course which explains the usage of the OMP Solution for sales & operations planning Target audience Users who wish to learn about sales & operations planning (S&OP) in the OMP Solution; S&OP Demand Planning Data Gathering & Setup (Analysis, Exception Reporting, Statistical Models, Data Aggregation) Routine Forecasting Cycle (Demand Change Reviews, Sales History and Future Forecast Adjustments, Unconstrained Forecast) Monitor & Improve Forecast Accuracy (Forecast Accuracy KPI, Forecast Value Added from Business Intelligence) Sales & S&OP is a structured planning process, based on a monthly cycle The objective is to improve the balance between future demands for the market's products and services, the organisation's resources and the supply of materials and services

Implement The S Op Process For Supply Chain Success Learn About Logistics

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

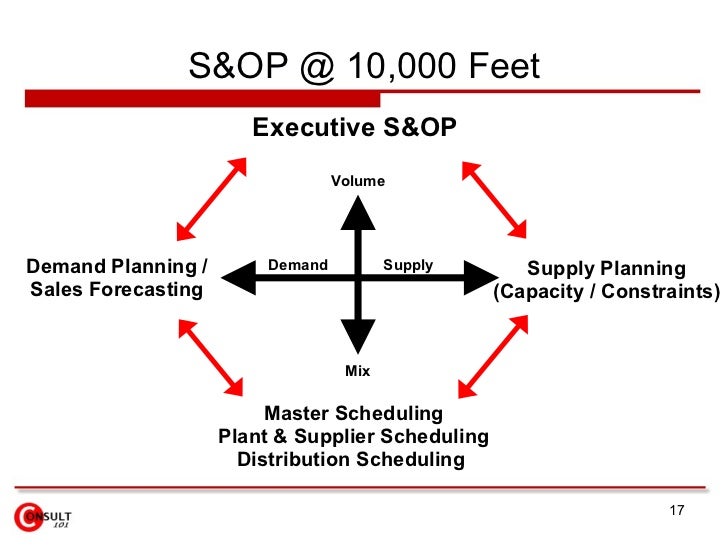

The Executive S&OP planning cycle is monthly, with provisions for midperiod revisions when major changes occur Executive S&OP is an aggregate planning tool It focuses on aggregate volumes, and only rarely looks at issues of mix, ie individual products, stock keeping units, customer orders and so onThe City of Miami issues Waivers intended to relieve practical difficulties in complying with the Miami 21 Code, when such Waivers meet a specific list of requirements Request a Hearing for a Planning or Zoning Application Have you submitted an application that requires a public hearing by either the Planning, Zoning and Appeals Board or theIt serves as the backbone of marketing in Sales and Operations Planning 2 Provide some examples of how a product's stage in its life cycle might impact production, inventory, and distribution plans There are 5 stages in the product life cycle which are the Development, Introduction, Growth, Maturity, and Decline Phase

What Is Sales And Operations Planning S Op Plex Demandcaster

What Is S Op Sales And Operations Planning Sap Insights

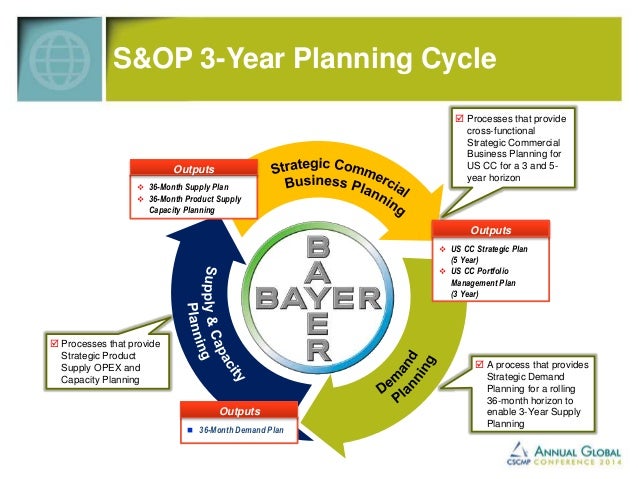

While Research & Development, Marketing, and Sales may be heading full steam ahead with their plans to get the latest product on the shelves, one area often overlooked is ensuring new products are part of Sales & Operations Planning (S&OP) Product Life Cycle Management (PLM), refers to the process of managing the entire product life cycle, from inception through end of life Measuring how well production is able to meet the planned output as determined by the S&OP team is key to maintaining tight delivery windows This metric is expressed as a percentage, calculated as (planned production actual production)/planned productionIBP represents the evolution of Sales and Operations Planning (S&OP) from the supply and demand balancing process developed in the early 1980s Today it is a process that drives the alignment of all functions across an organization, models and creates readiness for alternate outcomes, drives deployment of strategy, and enhances collaboration

S Op Introduction

What Is One Plan S Op Arkieva

The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a Sales and operations planning is a monthly business process enabling a company to determine the organizational goals It allows the organization to meet its operational, sales, and financial targets The process is typically the responsibility of a specific sales and operations planning team This includes the company's decision makers and• Decisions made during the monthly S&OP cycle • Decisions that need to be made today or in the future 5 Alignment review • Alignment of plans with the annual business plan • Alignment of plans with the company strategy 6 Inputs to the next S&OP cycle • Issues to be addressed • Improvements to be made • Review of actions assigned

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

While approaches vary among industries and companies, they typically focus on a monthly S&OP planning process with a longterm planning horizon ranging from 18 to 36 months The annual overall business plan ties in with all otherSales & Operations Planning (S&OP) The critical success factors Warehousing & distribution Customer Manufacturing Sourcing Assets & facilities Transportation Supply chain management GW ref 9026X067/AB/th initial version 10 Utrecht version 10 Page 2 Agenda A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful business SIOP will allow you to improve your forecasting, capacity and resource planning, cash flow, and inventory levels Yet there are many challenges with getting a proper, functioning SIOP process in place

Sales Operations Planning Consulting Supply Velocity

Sales And Operations Planning A Project Manager S Guide Asana

Get the most out of your S&OP process by integrating supply, demand, product and operational planning into one seamless process, enabled by one system With a single source of information and only one set of plans, S&OP becomes more transparent and efficient

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

Dp Vs S Op Process Flow

Smoother Execution Through S Op Logistics Management

Sales Operations Planning Scpi

Sales And Operations Planning S Op 101 Smartsheet

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

S Op Five Steps To Get Started Supply Chain Shaman

S Op More Important For Planning New Era Supply Chains Learn About Logistics

1

Sales And Operations Planning

Sales Operations Execution S Oe Vs S Op Toolsgroup

Ready To Upgrade Your S Op Process For Industry 4 0

1

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

What Are The Basic Elements Of The S Op Process Quora

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Ultimate Guide To Sales And Operations Planning S Op In 21

Sales Operations Planning Omnics

Sales And Operations Planning Process Self Assessment

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Sales And Operations Planning S Op

Sales And Operations Planning Explorescm

Sales And Operations Planning Relex Solutions

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

How S Op Improves Your Organization Tmc Fr

What Is S Op Sales And Operations Planning Explained Anaplan

Sales And Operations Planning S Op 101 Smartsheet

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

Supply Chain Graphic Of The Week The S Op Process

Achieve Excellence In Sales And Operations Planning Sapinsider

Achieve Excellence In Sales And Operations Planning Sapinsider

Improving Profitability With Sales Operations Planning Magellan Consulting Group

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

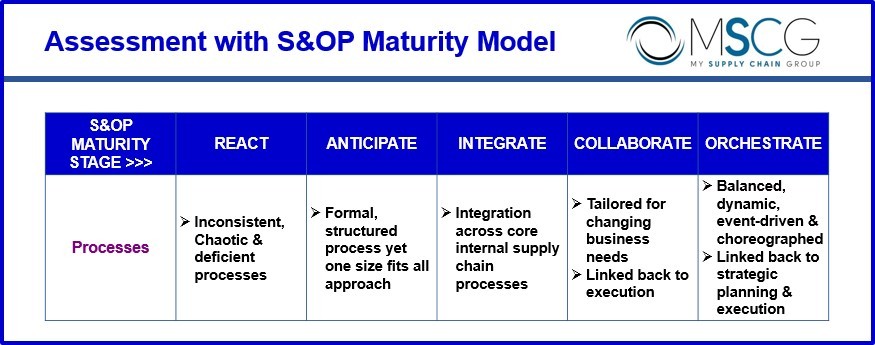

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Sales Operations Planning Engagement Model Tvo Maine Pointe

Who Should Own Sales And Operations Planning I Kinaxis

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning Business Forecasting Taruna Nagpal

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Software Sales And Operations Planning Qad Dynasys

1

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

What Is S Op How S Op Works Demand Planning Com

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

Software For Sales Operations Planning In Europe Supply Chain Movement

S Op Process

Sales And Operations Planning Powerpoint Template Sketchbubble

Sales And Operations Planning Relex Solutions

Sales And Operations Planning S Op Logistiikan Maailma

Oracle Demantra Sales And Operations Planning User Guide

S Op Five Steps To Get Started Supply Chain Shaman

What Is S Op Sales And Operations Planning Explained Anaplan

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Getting To Grips With Sales And Operational Planning Bloor Research

A Comprehensive Overview Of Sales And Operations Planning S Op

2

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

Sales And Operations Planning 4 Fundamental Concepts Sourcecodematrix

S Op Sales And Operations Planning And Sco

Sales And Operations Planning S Op Transform Your Business

Implementing An Integrated Sales And Operations Planning Process

2

Sales And Operations Planning Defined

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Pdf Sales And Operations Planning S Op An Overview

Sales And Operations Planning Report Do You Get Surprises

The S Op Journey Beyond The Supply Demand Match Organization And Ownership For The Demand Planning Process Aberdeen Strategy Research

Cscmp 14 Bayer Putting The S Back In S Op

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning Overview Chapter 1 Rb

Gartner Blog Network

2

Optimise Your Sales And Operations Planning S Op Slimstock Uk

Achieve Excellence In Sales And Operations Planning Sapinsider

What Are The Basic Elements Of The S Op Process Quora

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

0 件のコメント:

コメントを投稿